An Overview by Team ISSPL - Analytical Testing Laboratory in India

ToggleBakeries have the best business advantage because people love treating their loved ones with sweet baked items. The popularity of cakes and baked items increases with growing time. The essence of a soft and fluffy sponge cake can excite all buyers.

Even the sect of buyers with a health-conscious mindset can invest sufficiently in a cake. It could be part of the cheat meal! All consumers can pick baked items and enjoy the edible products to the best. The palates and tastes have evolved, and thus, the range of products in the bakery market has diversified. The market has become competitive.

The only thing that has remained the same over the years is the consumer’s desire for taste and quality. The quality and taste define the sales prospects of the product, defining its texture. Hence, all manufacturers must invest in the physical product testing drill.

The evaluation steps are essential during the earlier stages of baking and production to maximize sales, production efficiency, etc. It also helps maintain quality in the market, assuring consumer satisfaction.

Analyzing the flowability and texture

The ingredients in a baked item are diverse. The components are vital for manufacturers to ensure the perfect texture of the cake. It could be in the form of powdered grains and flour! All these are integral to promise a long shelf life. Quality maintenance is vital for baked items, and a Powder Flow Analyzer test can check critical properties like – powder flow, cohesion, and caking.

The prime characteristics determine the smooth processing, and you can focus on these baking traits to maintain the best quality. It is vital for maintaining consistency in the particle size and shape, moisture content, humidity, and surface friction. The process of powder flow analysis helps predict the powder behavior, optimizing the process accordingly. Stay assured of consistent quality with the flow analyzing steps.

The formulation makes the difference – The formulation of the baking dough is the most vital determinant in an edible baked product. It is vital for the physical and behavioral traits of the end-baked product. The textural properties of confectionary products depend on the foundation steps of the dough-making phase. There are various components used in the phase, including flour, water, oxygen from the air, etc.

The interaction between these components is prime for various reasons. The interaction also determines the rheological characteristics. Texture analysis can guarantee the ideal dough recipe and texture, maintaining the best quality all through without compromising the taste. Also, the texture analysis process helps prevent the chances of potential financial and material losses to the industrial manufacturer.

Testing the items – A need for the professionals

Bakery products have prime roles in the daily diet! The deliciousness of the simple-to-digest bakery and confectionary products makes them so popular. These have become an instant choice for all. Confectionary items and their manufacturers can boost business sales with enhanced quality checks. You can also ace the business game by following the best ways of quality checks and evaluating techniques. Especially for edible ready-to-eat products, quality plays a pivotal role.

It determines customer behavior as well. Hence, the makers and industrial honchos cannot take it lightly. Emphasize quality with the best-evaluating facilities brought by the top laboratories. Get a chance to utilize the opportunity and amplify the market with high-quality checking steps. Amplify the product quality and promote hygienic techniques in food preparation.

Significant aspects to note –

- Quality control and evaluation of the baking ingredients help ensure the consistency of the product. The manufacturers can mitigate the risks and avoid the chances of customer complaints.

- The foreign material in the baked product makes the edible item a threat to your health. It can also impact the brand. The foreign particle could be anything, but it increases the chances of serious health hazards. Hence, the manufacturers cannot take the risk and depend on rigorous testing.

- Manufacturers can also bypass the risks of overruling the label declarations. Evaluating the products also helps you combat practical issues that concern information and accuracy, and helps the baking stability and quality.

The future of bakery product testing

The technology across the world is evolving rapidly. The dynamic effects of inferior baked products can influence the landscape of food safety adversely. The best ways to detect contaminants, review the supply chains, and respond rapidly to potential threats are ideal for users and makers.

Innovative techniques for quality determination and package evaluation are essential to beat the competition. However, there are a few significant analytical lab-testing techniques that make a prominent impact. The testing facilities and accurate outcomes of the lab testing techniques also help improve consumer trust while enhancing the standards of the food industry.

With the rising variations and innovations in baked food products, the testing methods need to be updated over the time course. The essentiality of lab testing is known to all, and thus, the options to evaluate the products are expanding rapidly.

Innovate and evaluate – Ensure both.

Evaluating baked products is a vital part of the confectionery industry. The food industry depends on modern solutions to enhance its offerings. It also determines the creation of new flavors, delicacies, textures, and food experiences for the consumers. The responsibility of ensuring the safety and appropriateness of novel food creations makes the process critical in more ways than one. Industrialists can meet rigorous safety and quality standards with extensive food testing steps. Contrary to the concept of commoners, food testing does not restrict innovation.

In fact, it fuels it. The comprehensive tests on modern baking ingredients, formulations, and baking techniques help the manufacturers introduce unique products to the market with maximized confidence and trustworthiness. Ensure meticulous testing to exhibit the perfect taste, texture, and shelf life of the baked edibles.

Closing note

Rely on the testing facilities brought by IRCLASS Systems and Solutions Pvt Ltd (ISSPL) laboratory. With the best testing solutions and updated resources, evaluate the bakery products and analyze the ingredients with globally recognized quality standards.

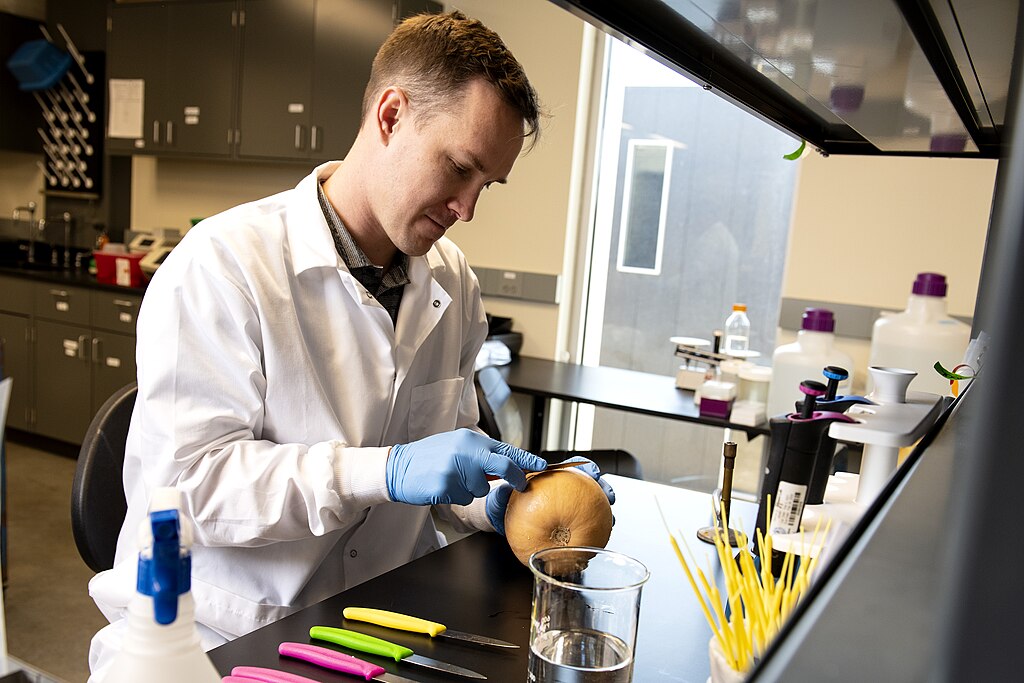

Ark. Agricultural Experiment Station, CC BY-SA 2.0 https://creativecommons.org/licenses/by-sa/2.0, via Wikimedia Commons