An Overview by Team ISSPL - Analytical Testing Laboratory in India

ToggleQuality control tests for tablets and evaluation of the sample tablets during the production stage are vital. It ensures a well-documented determination of the physical, chemical, mechanical, biological, and microbiological features of the medical tablets. The testing happens based on the norms and guidelines of in-house or Non-Pharmacopeial and Pharmacopeial standards like – BP, USP, Ph. Eur., etc. There are other guidelines like ICH. It is critical to design the tablets precisely and monitor the tablet production quality. In the long run, the quality control tests of tablets for evaluating the tablets’ physical, chemical, and bioavailability features make a significant impact on the effectiveness and utility of the products.

Diverse testing solutions – Know them rightly

There is more than one type of method used for the inspection and evaluation of tablets or for conducting quality control drills on them. All the quality control checks for tablets and evaluation techniques could be classified into three categories –

1. Non-Pharmacopeial or Non-Official Tests or In-House Tests– It includes the following property testing solutions –

- Appearance or Tablet Description

- Thickness and Diameter

- The hardness of the Tablet

- Organoleptic properties

2. Pharmacopeial or Official Tests– It offers an intensive and comprehensive quality testing solution for tablets –

- Identification Tests

- Friability Test

- Disintegration Test

- Weight Variation Test

- Uniformity of Dosage Unit Test

- Dissolution Test

- Assay Test

- Impurities Test

3. Specific Pharmacopeial Tests – These focus on the chemical properties and review the biological factors for better effectiveness, including the following –

- Microbiological Examination of Tablets

- Acid-Neutralizing Capacity

- Quality test of Splitting Tablets with Functional Scoring

- Water content

Features tested during the process

Do you have an overview of the critical aspects that matter significantly for tablet testing? Read on and know better –

- The appearance and branding – The overall appearance of a tablet is critical for patient compliance and identification. It has an industrial angle. The essentiality of monitoring the appearance of a tablet makes it an indispensable choice. It includes the measurement of the product, its shape, surface texture, diameter, density, thickness, color, absence or presence of an odor, taste, physical features and consistency, and many more. The scoreline and unique identification markings like the engraved logo on the tablets are also part of the features to be reviewed. Hence, appearance is a vital aspect for unofficial or in-house evaluation of the pills, thereby making an integral impact on the quality control steps.

- The distinctive features – The pharma and drug-making companies must use specific and unique markings for better branding. It also helps categorize the pills. It may be an embossed or engraved symbol or letter. The printing on the tablet is critical for unique identification.

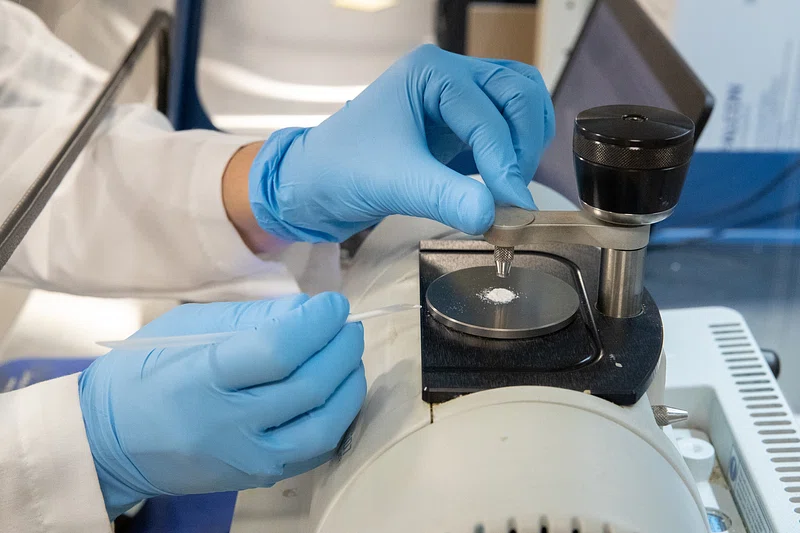

- Thickness, diameter, and more – The thickness of the tablet is an integral dimensional variable. It is related to the tablet compression process. Generally, the thickness and dimensional features get measured with the help of the new-age micrometer. The thickness must range within ±5% variation of the standard number. Why? Because it has an integral impact on marketing and controls the acceptance factor among the patients. Also, it makes the tablet packaging straightforward. The diameter and shape of the medical pills need to follow the norm, making it easy to control and punch during the compression stage. For instance, the USFDA recommends a standard diameter size for tablets as 8 mm or less than 8 mm. The diameter must not exceed 22 mm. Generally, the shape of the tablet must be round, oval, oblong, cylindrical, etc. The upper and lower surfaces may be flat, round, or tilted to various degrees. Why is it an integral part? Because the diameter and shape of the medical pill can impact esophageal transit, making it impactful for the treatment.

- Color and odor – Tablet color is vital for pill identification and patient acceptance. It has an industrial value as well. Several tablets, like ODT tablets and chewable pills have a typical odor, making it pleasant to taste. It is vital to improve patient acceptance and meet the taste requirements. Otherwise, it may hamper the treatment course and tablet effectiveness. In some tablets, one can find flavoring agents with the coating material to eliminate the foul odor of chemicals. Taste is a vital factor for patient acceptance, and for the ODT and chewable tablets, one can never ignore these factors.

- Physical sturdiness – One may need to break the pill into two parts and consume it twice. The breaking force of tablets is essential for these reasons. It is commonly called “hardness” in pharmaceutical terms. The tablets need to follow the norms stated by the industrial bodies to meet a definite amount of hardness, withstanding mechanical shocks. The mechanical shocks may be due to industrial handling, packaging, and transportation. Usually, oral pills have a hardness of 4 to 10 kg.

Uniform dosage – Better evaluation and production with tablet testing

In the pharma industry, the significance of producing uniform dosage is not challenging to understand. Why? Because the tablets are made of chemicals and bio-chemics. The uniformity of dosage units defines the degree of uniformity of the amount of the chemicals and drug substances. It is critical to ensure optimal consistency in every batch of manufactured dosage units. Each unit in a batch must have an equal drug content, ensuring optimal effectiveness for the treatment course. It is a pharmacopeia-evaluating technique, essential for the quality control checks for tablets. The uniformity of dosage units could be reviewed through – Content Uniformity and Weight Variation. Both are effective and help the company make better decisions for quality enhancement.

Get end-to-end solutions with the best lab facilities.

Obtaining the best equipment support during tablet testing makes the process hassle-free. The best-in-class testing facilities and efficient resources at the IRCLASS Systems and Solutions Pvt Ltd (ISSPL) Laboratory ensure an accurate outcome. Enjoy the benefits of testing the numerous properties of pharma products like pills, tablets, and capsules. Find affordable solutions without compromising industrial needs. Connect to the lab services for analytical and tablet testing and ease the requirements.